Essential Guide to Metal Corrosion Protection Techniques

Metal Corrosion Protection: Safeguarding the Integrity of Metal Structures

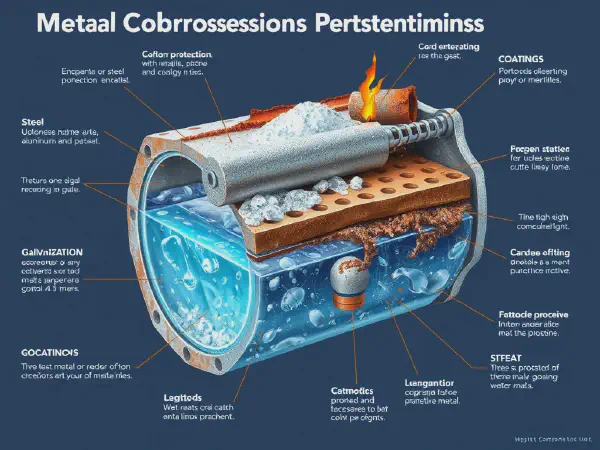

Metal corrosion protection is a critical aspect of maintaining the longevity and functionality of metal structures. It involves various techniques designed to prevent or slow down the deterioration of metal surfaces caused by environmental factors such as moisture, chemicals, and electrochemical reactions. Implementing effective corrosion protection is essential to avoid costly repairs and ensure safety in applications ranging from industrial machinery to household items.

The importance of metal corrosion protection cannot be overstated. Corrosion can lead to significant material loss, reduced mechanical strength, and impaired functionality of metal items. This deterioration not only compromises the physical integrity of structures but can also pose severe safety risks in industries such as construction, automotive, and aerospace. By prioritizing corrosion protection, industries can extend asset lifecycles, minimize maintenance costs, and enhance overall safety.

Several factors influence the rate and extent of metal corrosion, including the type of metal, environmental conditions, and the presence of corrosive agents. Understanding these factors is crucial for developing effective corrosion protection strategies. For instance, metals such as aluminum and stainless steel offer more natural resistance to corrosion due to their oxide layers, while others like iron and steel are more prone to rusting in moist conditions. A tailored approach to metal corrosion protection is necessary to counteract these vulnerabilities.

Corrosion can manifest in different forms, such as uniform corrosion, pitting, galvanic corrosion, and corrosion fatigue. Each type requires specific protective measures. For example, galvanic corrosion, which occurs when two dissimilar metals are in contact, can be mitigated through proper material selection and insulation techniques. Understanding these variations allows for a more targeted approach to metal corrosion protection, ensuring stronger and more reliable outcomes.

Overall, metal corrosion protection is not just a maintenance task; it is a science that combines material engineering, chemistry, and environmental science to develop effective solutions for preserving metal integrity. Industries that proactively invest in corrosion protection not only gain a competitive edge but also contribute to sustainable practices by reducing waste and resource consumption.

Effective engineering designs prioritize durability, making Metal corrosion protection crucial in preventing costly infrastructure failures.

Types of Metal Corrosion

Chemical corrosion is primarily caused by the reaction of metals with corrosive chemicals in their environment. Factors such as acidic or alkaline pH levels, temperature, and the presence of oxidizing agents significantly influence the rate of chemical corrosion. The effects can be severe, leading to complete structural failure if not managed properly. Regular inspections and maintaining protective coatings can help mitigate this risk.

Electrochemical corrosion, on the other hand, involves the flow of electric current due to the presence of electrolytes, leading to anodic and cathodic reactions. It is important to understand the processes involved in electrochemical corrosion to prevent unexpected failures. Techniques such as sacrificial anode application can be used to divert corrosion away from important components and ensure the metal remains intact.

Galvanic corrosion occurs when two different metals are in electrical contact in the presence of an electrolyte, resulting in accelerated corrosion of the less noble metal. Prevention techniques include the use of insulating materials to avoid direct contact and the application of protective coatings that act as barriers against corrosive elements.

Pitting corrosion is characterized by the formation of small, localized pits on the metal surface that can lead to structural weaknesses. Identifying and managing pitting corrosion involves regular monitoring and employing corrosion-resistant materials or coatings specifically designed to handle this type of corrosion. Early detection plays a critical role in preventing pitting from leading to severe damage.

Corrosion Protection Methods

Different corrosion protection methods can be applied depending on the environment and the metal type. Coating application techniques, such as painting, galvanizing, or powder coating, form a barrier between the metal surface and corrosive elements. These coatings not only enhance aesthetics but also provide long-lasting protection against environmental damage. Selecting the right type of coating is vital for achieving the best results.

Cathodic protection is a widely used method to prevent corrosion on metal surfaces, particularly submerged or buried structures. It works on the principle of making the metal surface a cathode in an electrochemical cell, thereby reducing the corrosion rate. This can be achieved through impressed current systems or sacrificial anode systems, each with its own advantages depending on the application's requirements.

Corrosion inhibitors are chemical compounds that, when added to the corrosive environment or applied to the metal surface, can significantly reduce corrosion rates. There are various types of inhibitors available, including anodic, cathodic, and mixed inhibitors, each designed to target specific corrosion mechanisms. Analyzing the effectiveness of these substances in different environments is essential for selecting the right inhibitor for a given application.

Environmental control plays a crucial role in reducing corrosion rates. This can involve measures such as controlling humidity, temperature, and exposure to corrosive chemicals. Implementing protective measures such as using corrosion-resistant materials and designing for drainage can greatly mitigate the impact of environmental conditions on metal structures, ensuring their longevity and reliability.

Corrosion in Different Industries

In marine applications, corrosion poses significant challenges due to the constant exposure to saltwater and humidity. Solutions such as protective coatings, cathodic protection, and regular maintenance schedules are essential to prevent corrosion-related failures in ships, offshore platforms, and other maritime structures. Employing these strategies allows for safer and more efficient marine operations.

Within construction, preventing corrosion damage in structural materials is paramount to ensuring safety and integrity. Using corrosion-resistant materials like stainless steel and applying protective coatings can help extend the lifespan of building components. Regular inspection and maintenance play a vital role in identifying early signs of corrosion, allowing for timely interventions.

The automotive industry is highly affected by corrosion, particularly from exposure to moisture, road salts, and pollutants. Protecting metal components involves utilizing coatings, galvanization, and material selection to minimize corrosion risks. Additionally, manufacturers are constantly exploring innovations to improve corrosion resistance, ensuring vehicles remain safe and reliable over their service lives.

In the oil and gas industry, corrosion management strategies are crucial due to the harsh environments in which equipment operates. This includes using corrosion-resistant materials, implementing cathodic protection systems, and conducting routine inspections and testing. Effective corrosion management not only extends the lifespan of infrastructure but also mitigates safety and environmental risks associated with corrosion failures.

Corrosion Testing and Analysis

Laboratory methods for corrosion testing involve standardized procedures to evaluate the corrosion resistance of materials under controlled conditions. These tests enable researchers and engineers to determine the effectiveness of various coatings, inhibitors, and materials, providing critical data for developing effective corrosion protection strategies.

Field testing is equally important as it assesses the material performance under real-world conditions. These tests help understand how environmental factors affect corrosion rates in specific applications and can inform maintenance and protection strategies tailored to those conditions.

Analyzing corrosion failures through case studies provides valuable insights into common pitfalls and challenges encountered in corrosion management. Such analyses enable industries to learn from past mistakes, leading to improved practices and material selections that can prevent similar failures in the future.

Predictive modeling for corrosion evaluation utilizes advanced algorithms and simulations to forecast corrosion behavior and deterioration over time. This proactive approach helps industries plan maintenance schedules, budget for repairs, and select appropriate corrosion protection measures based on anticipated conditions.

Innovations in Corrosion Protection

Nanotechnology has emerged as a groundbreaking advancement in coatings for corrosion protection. Utilizing nanoparticles can enhance the barrier properties and durability of coatings, making them significantly more effective against corrosion. Innovations in this field are continuously being explored to develop more efficient, eco-friendly solutions to combat corrosion.

Smart materials for corrosion resistance are being researched for their potential to self-heal and respond to environmental changes. These materials can adapt their properties based on surrounding conditions, providing an innovative approach to corrosion protection. The integration of these technologies holds promise for future applications in various industries.

Bio-inspired corrosion protection solutions mimic natural processes found in nature to enhance corrosion resistance. Researchers are studying organisms that naturally resist corrosion, aiming to replicate their mechanisms in coatings and materials. This bio-inspired approach can lead to more sustainable and effective corrosion protection methods.

Future trends in corrosion technology include the development of predictive maintenance systems that leverage machine learning and IoT to monitor corrosion in real time. These advancements will enable industries to respond proactively to corrosion threats, thereby extending the lifespan of materials and structures while reducing costs associated with unscheduled maintenance.

Regulations and Standards for Corrosion Protection

Industry standards for metal corrosion prevention are essential to ensure safety and reliability. Standards from organizations such as ASTM International and NACE International provide guidelines for best practices in corrosion protection, including material selection, coating applications, and testing methodologies.

Environmental regulations also impact corrosion practices, pushing industries to adopt more sustainable materials and methods for corrosion protection. Adhering to these regulations not only helps protect the environment but also ensures compliance with legal requirements, reducing liability risks for companies.

Safety guidelines for corrosion-related projects emphasize the importance of risk assessments, proper training, and adherence to maintenance schedules to minimize hazards associated with corrosion. Ensuring worker safety is paramount in all industries, and establishing clear guidelines for managing corrosion risks is crucial.

ISO standards in corrosion protection methods provide an internationally recognized framework for ensuring quality and consistency in corrosion management practices. Adhering to these standards fosters accountability and trust, making them essential to effective corrosion protection across industries.